Characterized by its favorable mechanical attributes, notable weldability, resistance to corrosion, and extensive application in extrusion procedures, 6061 aluminum coil has established itself as one of the most commonly utilized aluminum alloys for general-purpose applications.

Its availability extends to a range of pre-tempered and tempered grades, such as the annealed 6061-O, solutionized and artificially aged 6061-T6. and solutionized, stress-relieved, stretched, and artificially aged 6061-T651. The versatile nature of this alloy renders it suitable for engineering and structural purposes, as well as the construction of boats, furniture, and transportation equipment.

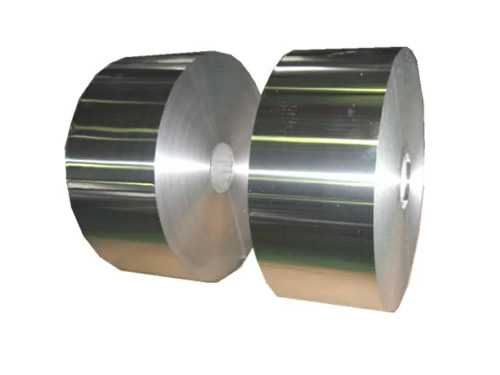

| 6061 Aluminum Coil | ||

| Standard | JIS, AiSi, ASTM, GB, DIN, EN etc | |

| Grade | 1000 Series,2000,3000 Series,4000Series,5000Series,6000Series,7000Series,8000Series,,9000Series | |

| Surface | Coated, Embossed,Brushed, polished, Anodized,etc | |

| OEM service | Perforated, Cutting special size, Doing flatness, Surface treatment,etc | |

| Delivery Time | Within 3 days for our stock size,15-20days for our production | |

| Application | Construction filed, Ships building industry, Decoration, Industry,Manufacture,Machinery and hardware fields, etc | |

| Sample | Free and available | |

| Package | Export standard package: bundled wooden box, suit for all kinds of transport,or be required | |

Available Size Range

| Dimension | Range |

| Thickness | 0.2 ~ 6.0 mm |

| Width | 600 ~ 2,600 mm |

* The thickness can be up to 10mm for coil stock (mother coil for cold rolling).

- Standard Width and Length: 1000mm, 1250mm, 1500mm, 1219mm, 1524mm

- Surface Finish: Mill finish, unless otherwise specified

- Surface Protection:

Without paper interleaved for all aluminum coils

With PE/PVC filming on main side (if specified)

Chemical Properties of Frequently-used :

| Grade | Al | Mg | Si | Fe | Mn | Cu | Ti | Cr | Zn |

| 6061 | 97.9% | 0.6%-1.2% | 0.4%-0.8% | 0.7%-1.2% | 0.15% | 0.15%-0.4% | 0.15% | 0.04%-0.35% | 0.25% |

General overview

Aluminum has low density, much lighter than common metals like steel and copper, suitable for lightweight structures. Its surface is easy to process with various surface treatments such as anodizing, painting, and coating, thus enhancing its decorative properties.